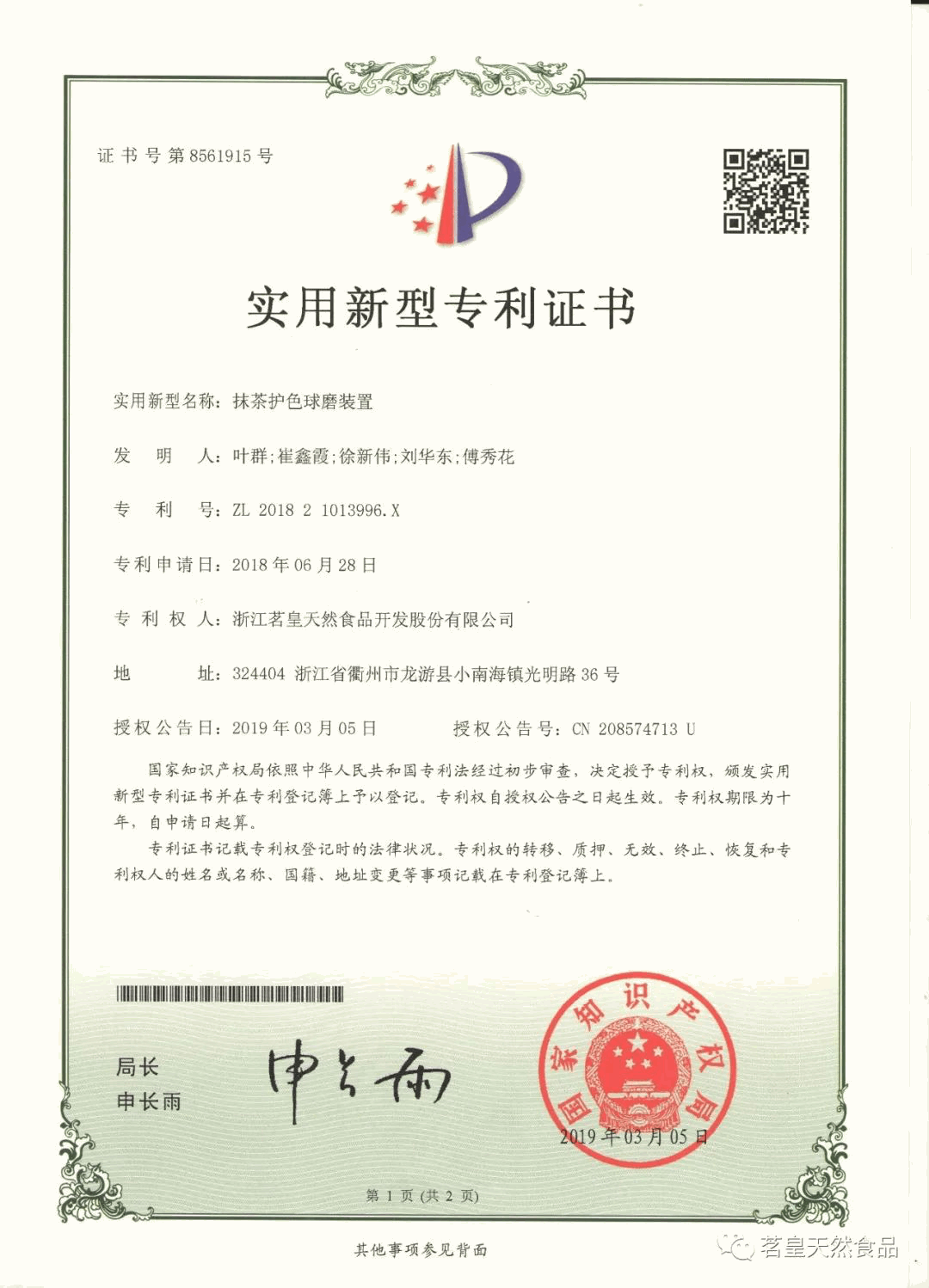

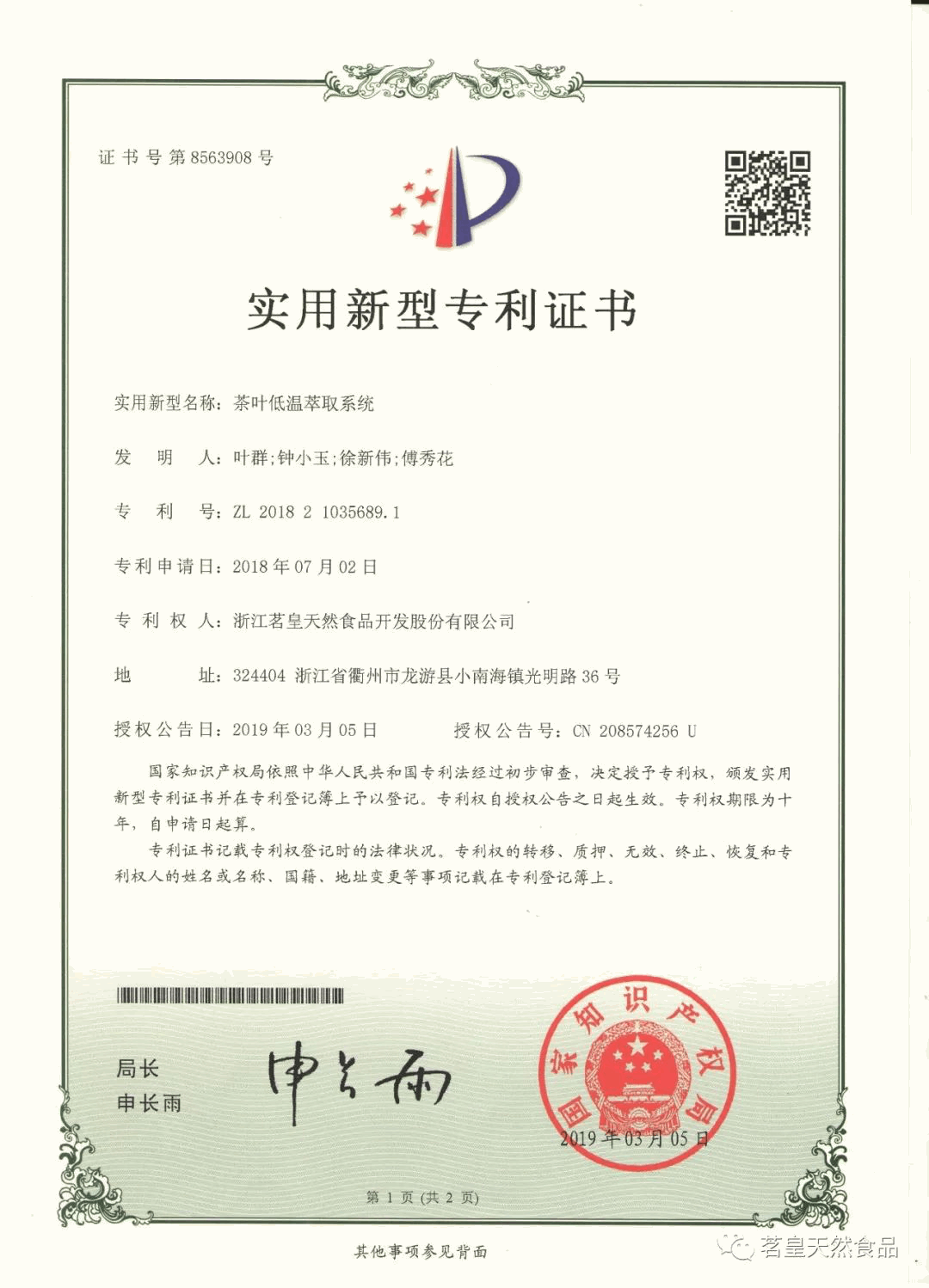

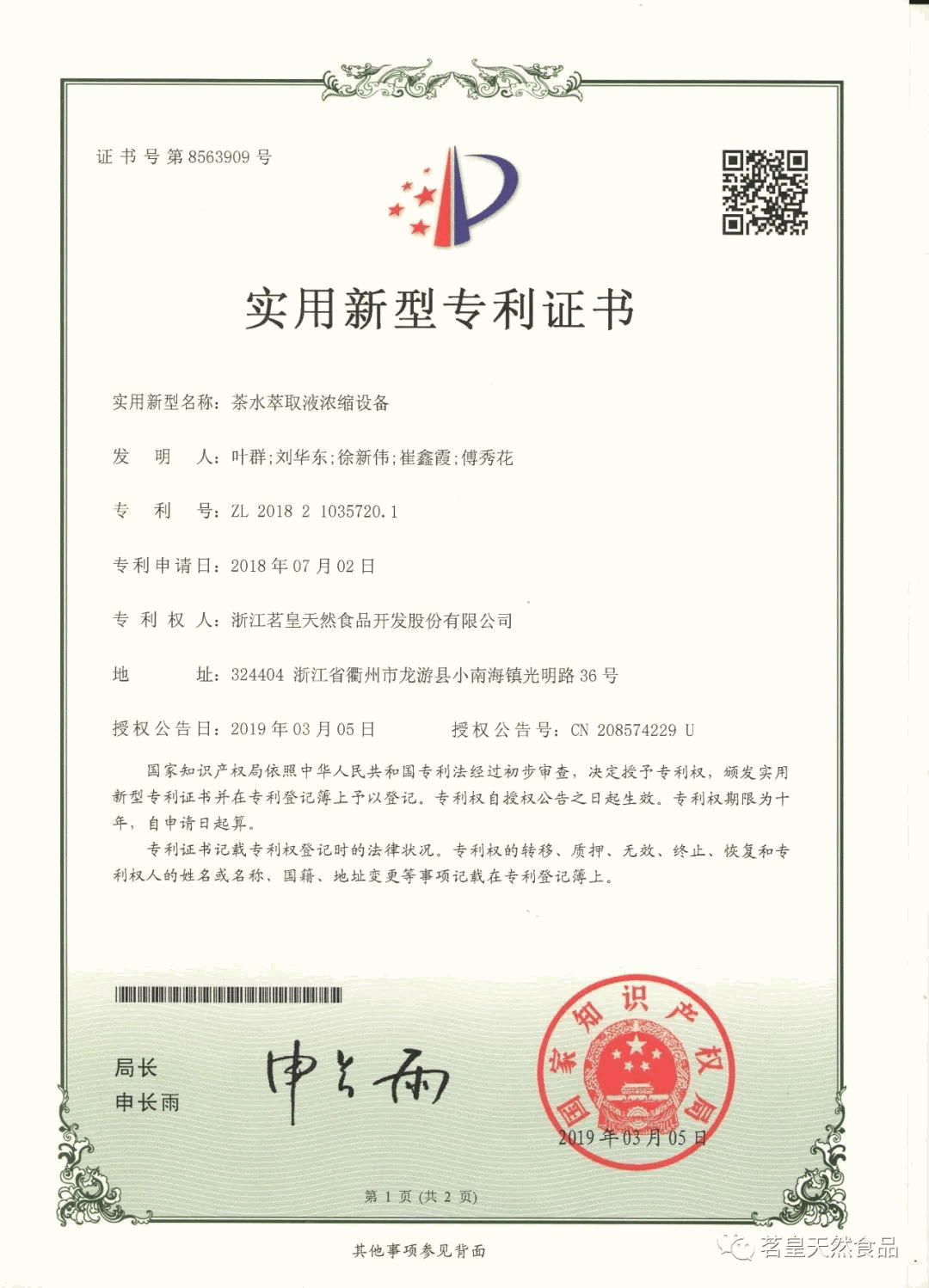

Warmly congratulate our company on winning the"Utility Model Patent Certificate" issued by the State Intellectual Property Office for the three utility model technologies of "Matcha Color Protection Ball Milling Device", "Tea Low Temperature Extraction System" and "Tea Extract Concentration Equipment"

Mata Color Protection Ball Milling Device

Ball mill is a common grinding device. The existing ball mill generally uses the centrifugal force of rotation to lift the internal grinding ball and crush the material through the interaction between the grinding ball and the material. Therefore, this ball mill will generate a lot of heat during the grinding process, and the temperature in the grinding cylinder is high. Tea will be oxidized by oxygen due to the high temperature in such ball mill, The utility model provides a ball milling device to protect the color of tea, so as to achieve the following purposes:① The utility model is always under the protection of protective gas during the milling process, so it is used to mill tea, and the tea will not be oxidized by oxygen to turn yellow; ② The utility model is equipped with a heat exchange chamber outside the grinding cylinder. Through heat exchange, the grinding cylinder can be kept at a low temperature, further ensuring that the tea will not be oxidized by oxygen and turn yellow

Tea low-temperature extraction system

Extract tea is made from finished tea or semi-finished tea by using hot water to extract the soluble matter in the tea and filter the tea residue. Some of them are concentrated and dried to prepare solid or liquid tea. The current technology has higher extraction temperature during tea extraction, which will cause the color of the tea extract to darken, and the content of catechin and caffeine in the tea extract extracted at low temperature is less, making the bitter taste softer, Help to improve the flavor. In view of the above problems, the utility model provides a tea low-temperature extraction system to achieve the following purposes: The utility model uses the method of vacuumizing to discharge the material, which greatly shortens the discharge time and improves the extraction efficiency

Tea Extract Concentration Equipment

According to the current concentration method of tea concentrate, the steam generated in the concentrator cannot be reused, the steam utilization rate is low, the energy consumption is high, and the production cost is high. In view of the above problems, the utility model provides a tea extract concentration equipment to achieve the following purposes:① The steam generated in the concentrator of the utility model can be reused, improve the steam utilization rate, thereby reducing energy consumption and reducing costs; ② The utility model can continuously discharge materials, and has higher production efficiency compared with the intermittent production mode of the existing technology; ③ The utility model can reduce the pressure in the concentrator, thereby reducing the temperature required for concentration and shortening the discharge time

The acquisition of the national utility model patent fully reflects our company's independent R&D and innovation capabilities, improves the company's core competitiveness, improves the company's brand awareness, and provides strong scientific and technological support for the company's future development

ZGNANB No. 33082502000102

ZGNANB No. 33082502000102